- +49 6834 - 9210 - 0

- info@ktp-online.de

-

Find the right transport container now

Discover our innovative product solutions and packaging systems. Find the right container for your requirements.

Our container systems can be tailored to your needs with a wide range of equipment options. Discover now.

-

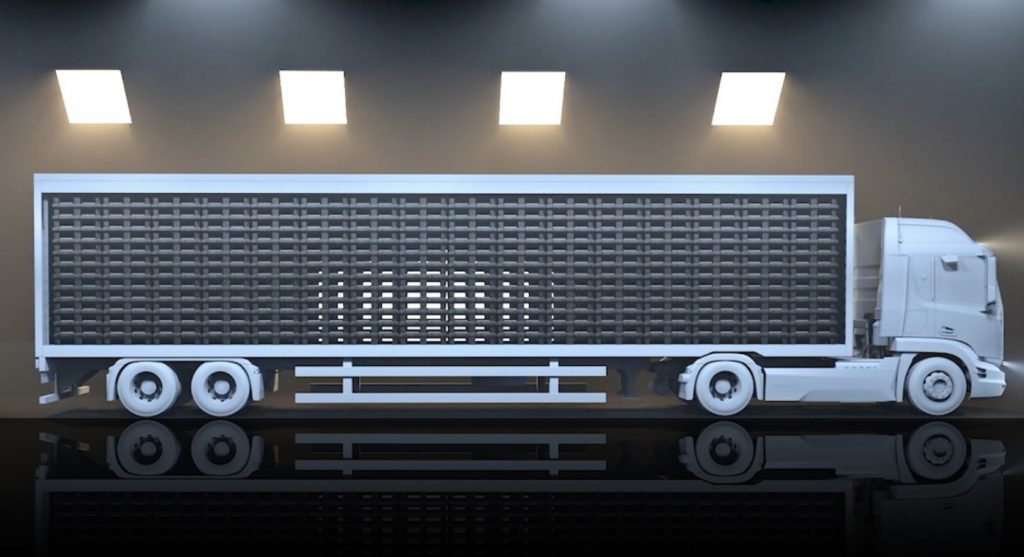

Carrier systems

The solution for the transport and storage of small stackable containers (VDA) and foam containers (EPP/EPE).

-

Inside packaging

Individual and customised – Numerous types of inner packaging can be integrated into KTP containers.

-

Specialised containers

Up to any challenge –

We develop and produce customised packaging solutions.

-

Solutions & Services

Excellent service is a matter of course for us – discover the KTP “all-round carefree package”.

We accompany you throughout the entire process: from the determination of requirements to the optimisation of the logistical process chain to after-sales service. We are here for you!

-

Industries

Discover the advantages of our systems and product variants for your area of application.

Automotive

Industrial manufacturing

Electronics

Pharmaceutical & Health Care Industy

Agricultural Technology

Trade & Logistics Individual products

for your industryand your requirements.